Reliable Partners for Agricultural Machinery: Abrasion- and Twist-Resistant Hydraulic Hoses

Release time:

2025-08-28

Reliable Partners for Agricultural Machinery: Abrasion- and Twist-Resistant Hydraulic Hoses

Why Do Agricultural Machines Need Specialized Hydraulic Hoses?

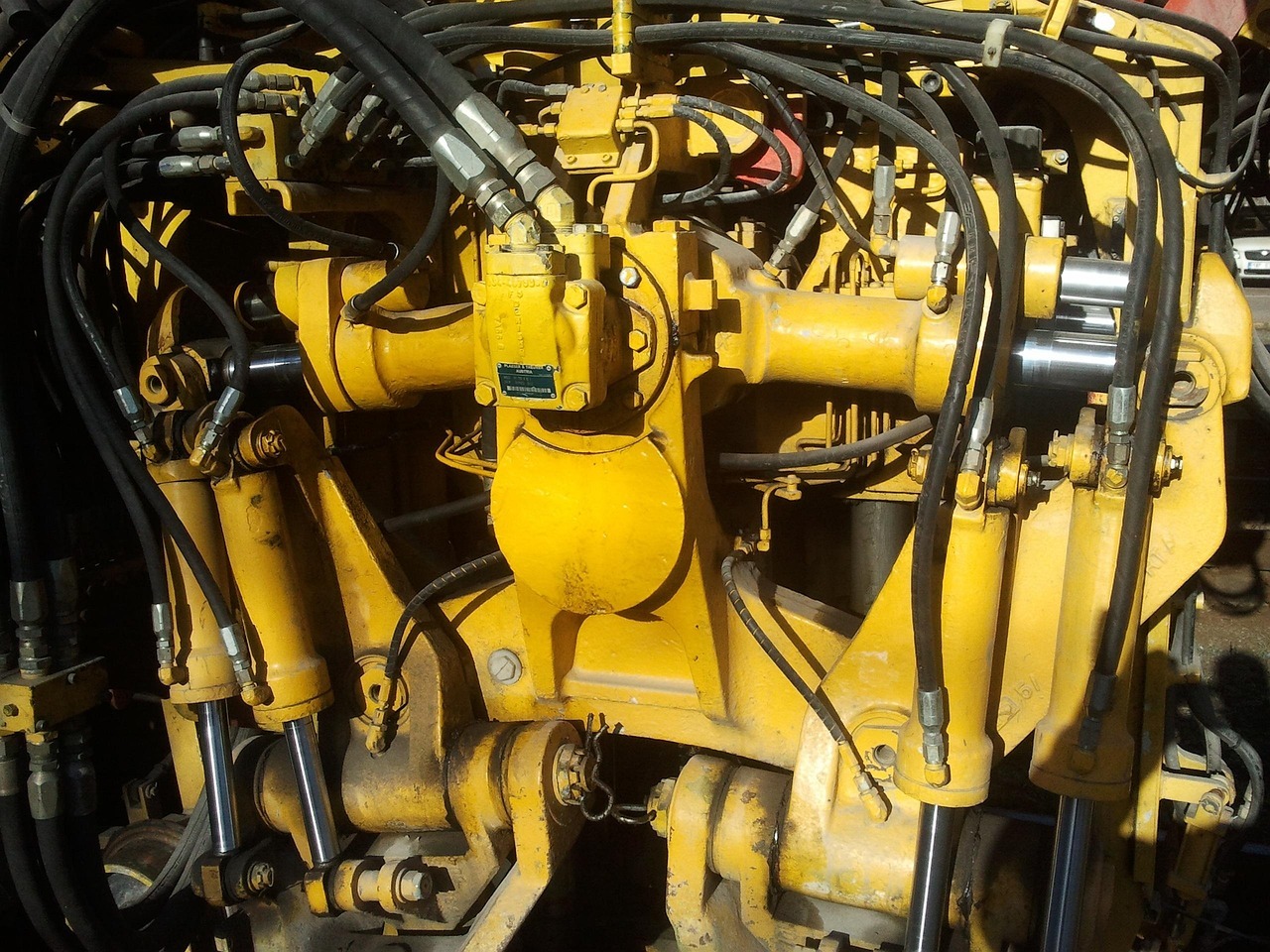

Agricultural machinery works in some of the toughest conditions. Dust, soil, gravel, and crop residues constantly rub against hose surfaces, while frequent lifting, turning, and folding motions create repeated bending and twisting. When a hose fails during peak season, downtime means not only expensive repairs but also delayed harvesting schedules.

The Real Causes of Hose Failure

The two most common failure modes in agricultural hydraulic hoses are abrasion and twisting. Continuous contact with hard surfaces or metal parts gradually wears away the outer rubber layer, exposing the steel reinforcement and reducing strength. At the same time, improper routing or high-frequency movements can cause hoses to twist under pressure, leading to wire fatigue and eventually rupture. These failures result from the combined effects of harsh environments and incorrect installation—not just material quality.

How to Achieve Abrasion and Twist Resistance

To overcome these challenges, hose design must combine strong external protection with internal flexibility. Senflow’s wire braid hydraulic hoses, which meet SAE 100RAT and EN853 standards, feature a thickened abrasion-resistant outer sleeve and oil-resistant materials, providing enhanced protection against wear and chemical exposure. A highly abrasion-resistant outer layer or polyurethane sleeve reduces surface damage, while high-flex steel reinforcement and optimized braid angles minimize the impact of torsion. Installing swivel fittings in critical positions and maintaining proper bend radius further improves durability. Smart routing that avoids constant contact with sharp edges or metal surfaces is also essential.

Senflow Solutions for Agricultural Machinery

Senflow hydraulic hoses are engineered for the realities of modern farming. With reinforced abrasion-resistant covers, anti-twist construction, and rigorous pressure pulse testing, they deliver consistent performance in demanding field conditions. From seeding to harvesting, Senflow hoses keep machines running longer, reduce maintenance interruptions, and protect your schedule during the busiest season. When reliability matters most, Senflow provides the confidence you need for uninterrupted operations and lower total cost of ownership.

Related News

Hydraulic Hose Failures in Mining Equipment: Causes and Prevention

Hydraulic hose failures are a major challenge in mining, caused by vibration, pressure surges, abrasion, and extreme conditions. This article explains how failures develop and highlights solutions: EN 856 4SH hoses, MSHA flame resistance, MA certification, and synthetic rubber covers resistant to oil, weather, and wear. With proper installation and maintenance, hoses become reliable assets that keep mining operations safe and productive.

Technical Overview: Systematic Pathways of Oilfield Stimulation

Oilfield stimulation is essential for maintaining production as reservoir pressure declines. Acidizing restores flow near the wellbore, hydraulic fracturing opens tight formations, and EOR methods like chemical flooding, CO₂ injection, and thermal recovery extend field life. A system-level approach ensures the right method is applied for geology and economics. Future trends focus on precision, efficiency, and sustainability. Reliable equipment such as Senflow’s high-performance hoses supports safe and efficient fluid delivery in acidizing, fracturing, and thermal operations.

Hydraulic Fracturing Networks: The Underground Highway of Shale Gas

Hydraulic fracturing and acid fracturing are the backbone of shale oil and tight gas development. Behind every successful fracturing job lies not only fracture mechanics and reservoir engineering but also the reliability of high-performance hoses that deliver fracturing fluids safely under extreme pressure. This article explains how fracture networks form—the “underground highway” of unconventional resources—and why advanced hoses like Senflow super abrasion-resistant UPE hoses are vital for efficiency, safety, and production gains.

Durable Sandblasting Hoses: Ensuring Efficiency and Safety on Construction Sites

Large-scale construction projects demand not only robust materials but also reliable preparation processes. Sandblasting hoses play a critical role in cleaning steel surfaces, yet they face harsh conditions, including abrasion, extreme temperatures, and frequent bending. Senflow’s abrasion-resistant, weatherproof hoses provide consistent performance, extending service life, reducing downtime, and supporting safe, efficient project execution across diverse construction environments.

High-Performance Frac and Oil Hoses for Hydraulic Fracturing Operations

Hydraulic fracturing is essential for extracting hydrocarbons from low-permeability reservoirs. Safe, efficient fluid and proppant transport relies on high-pressure, super abrasion- and acid-resistant frac hoses and oil hoses. Senflow’s reinforced hoses ensure reliable performance under extreme pressure, abrasive conditions, and harsh chemicals, supporting stable and effective hydraulic fracturing works.