Technical Overview: Systematic Pathways of Oilfield Stimulation

Release time:

2025-09-16

Oilfield Lifecycle and the Need for Stimulation

In the early stage of oilfield development, reservoir pressure allows crude oil to flow naturally into the wellbore. Over time, this energy declines, leading to reduced output. To extend oilfield lifecycle and maximize recovery, engineers employ oilfield stimulation techniques. These range from near-wellbore treatments to large-scale hydraulic fracturing and tertiary recovery (EOR), forming a systematic toolbox that underpins modern oilfield engineering.

Near-Wellbore Treatments: Restoring Flow Channels

When formation plugging or damage occurs near the wellbore, acidizing is the most effective solution. Hydrochloric acid or mud acid dissolves carbonates and clays, restoring pore connectivity and enabling fluid flow. In these operations, reliable acidizing hoses are critical for safe acid delivery. Acidizing is cost-effective, provides quick results, and is widely applied in carbonate reservoirs or mud-damaged sandstones.

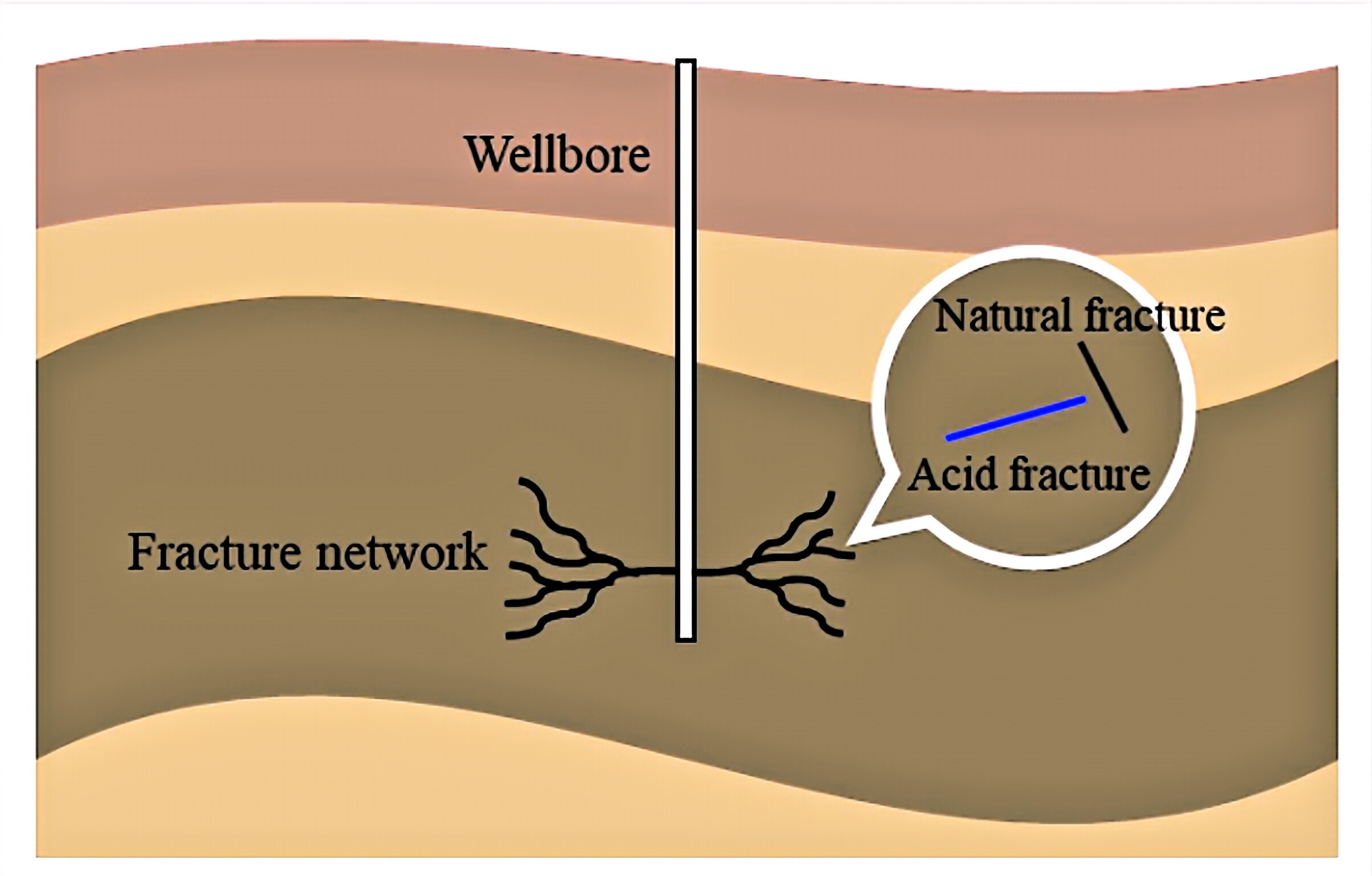

Reservoir Stimulation: Creating Artificial Fractures

For tight or low-permeability formations, hydraulic fracturing is essential. High-pressure fluids create cracks, and proppants such as quartz sand or ceramics keep them open, forming conductive pathways. Hydraulic fracturing is central to shale oil and shale gas development, where hydraulic fracturing hoses (frac hoses) ensure safe, high-pressure delivery of fracturing fluids. Senflow offers super abrasion-resistant UPE hoses, specifically engineered for fracturing operations in both onshore and offshore oilfields, helping maximize production efficiency.

Enhanced Oil Recovery: Altering Fluid Properties and Energy Balance

In later development stages, Enhanced Oil Recovery (EOR) methods are introduced. Chemical flooding with polymers, surfactants, or ASP formulations improves sweep efficiency, while CO₂ miscible flooding reduces oil viscosity and replenishes pressure. Thermal recovery techniques such as steam huff-and-puff or flooding target heavy oil reservoirs, requiring durable oilfield hoses that withstand high temperatures and corrosive media.

System Approach and Future Trends

Oilfield stimulation is not about applying a single technique but integrating acidizing, fracturing, and EOR into a tailored strategy that fits geological and economic conditions. Advances in digital modeling and material science now enable more precise stimulation design. Equally important is the reliability of supporting equipment—oilfield hoses, drilling hoses, and frac hoses built for acid resistance, high pressure, and super abrasion performance. By deploying Senflow UPE hoses with multi-spiral steel reinforcement, operators ensure safe and efficient stimulation workflows, extending oilfield productivity and sustainability.

Related News

Hydraulic Hose Failures in Mining Equipment: Causes and Prevention

Hydraulic hose failures are a major challenge in mining, caused by vibration, pressure surges, abrasion, and extreme conditions. This article explains how failures develop and highlights solutions: EN 856 4SH hoses, MSHA flame resistance, MA certification, and synthetic rubber covers resistant to oil, weather, and wear. With proper installation and maintenance, hoses become reliable assets that keep mining operations safe and productive.

Technical Overview: Systematic Pathways of Oilfield Stimulation

Oilfield stimulation is essential for maintaining production as reservoir pressure declines. Acidizing restores flow near the wellbore, hydraulic fracturing opens tight formations, and EOR methods like chemical flooding, CO₂ injection, and thermal recovery extend field life. A system-level approach ensures the right method is applied for geology and economics. Future trends focus on precision, efficiency, and sustainability. Reliable equipment such as Senflow’s high-performance hoses supports safe and efficient fluid delivery in acidizing, fracturing, and thermal operations.

Hydraulic Fracturing Networks: The Underground Highway of Shale Gas

Hydraulic fracturing and acid fracturing are the backbone of shale oil and tight gas development. Behind every successful fracturing job lies not only fracture mechanics and reservoir engineering but also the reliability of high-performance hoses that deliver fracturing fluids safely under extreme pressure. This article explains how fracture networks form—the “underground highway” of unconventional resources—and why advanced hoses like Senflow super abrasion-resistant UPE hoses are vital for efficiency, safety, and production gains.

Durable Sandblasting Hoses: Ensuring Efficiency and Safety on Construction Sites

Large-scale construction projects demand not only robust materials but also reliable preparation processes. Sandblasting hoses play a critical role in cleaning steel surfaces, yet they face harsh conditions, including abrasion, extreme temperatures, and frequent bending. Senflow’s abrasion-resistant, weatherproof hoses provide consistent performance, extending service life, reducing downtime, and supporting safe, efficient project execution across diverse construction environments.

High-Performance Frac and Oil Hoses for Hydraulic Fracturing Operations

Hydraulic fracturing is essential for extracting hydrocarbons from low-permeability reservoirs. Safe, efficient fluid and proppant transport relies on high-pressure, super abrasion- and acid-resistant frac hoses and oil hoses. Senflow’s reinforced hoses ensure reliable performance under extreme pressure, abrasive conditions, and harsh chemicals, supporting stable and effective hydraulic fracturing works.