Understanding Hydraulic Hose Markings

Release time:

2025-08-15

Understanding Hydraulic Hose Markings

Hydraulic hoses are critical components in fluid power systems, and understanding their markings is essential for safe and reliable operation. Selecting the wrong hose can lead to leaks, equipment failure, or safety hazards. Most hoses feature printed markings along their length, conveying key information such as the manufacturer, hose type, size, pressure rating, temperature range, and applicable standards.

Decoding Hose Information

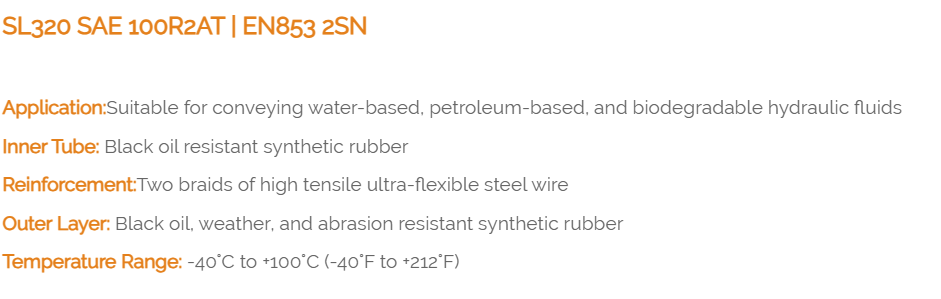

For example, a marking like “SAE 100R2AT - 1/2" - 350 bar - -40°C to +100°C” provides multiple layers of information. “SAE 100R2AT” indicates a high-pressure hose featuring a two-wire braid construction that meets SAE standards. “1/2"” specifies the internal diameter, affecting flow rate and fitting compatibility. “350 bar” denotes the maximum working pressure, and “-40°C to +100°C” defines the safe operating temperature range. Understanding these parameters ensures the hose can handle the system’s pressure and environmental conditions.

Professional Support for Hose Selection

Senflow offers a dedicated technical support team to assist with hose selection for complex hydraulic systems. By analyzing system pressure, temperature, fluid type, and dynamic conditions, Senflow experts recommend hoses that optimize performance, extend service life, and reduce operational risks. This professional guidance ensures users choose hoses that are fully compatible with their specific applications.

Practical Considérations

Special attention should be paid to hoses used with aggressive fluids, extreme temperatures, or highly dynamic systems, as proper selection directly impacts system reliability. Regularly checking that markings remain legible ensures traceability and supports preventative maintenance. In summary, hydraulic hose markings are essential technical indicators that enable informed decisions and maintain hydraulic systems safely and efficiently.

Related News

Hydraulic Hose Failures in Mining Equipment: Causes and Prevention

Hydraulic hose failures are a major challenge in mining, caused by vibration, pressure surges, abrasion, and extreme conditions. This article explains how failures develop and highlights solutions: EN 856 4SH hoses, MSHA flame resistance, MA certification, and synthetic rubber covers resistant to oil, weather, and wear. With proper installation and maintenance, hoses become reliable assets that keep mining operations safe and productive.

Technical Overview: Systematic Pathways of Oilfield Stimulation

Oilfield stimulation is essential for maintaining production as reservoir pressure declines. Acidizing restores flow near the wellbore, hydraulic fracturing opens tight formations, and EOR methods like chemical flooding, CO₂ injection, and thermal recovery extend field life. A system-level approach ensures the right method is applied for geology and economics. Future trends focus on precision, efficiency, and sustainability. Reliable equipment such as Senflow’s high-performance hoses supports safe and efficient fluid delivery in acidizing, fracturing, and thermal operations.

Hydraulic Fracturing Networks: The Underground Highway of Shale Gas

Hydraulic fracturing and acid fracturing are the backbone of shale oil and tight gas development. Behind every successful fracturing job lies not only fracture mechanics and reservoir engineering but also the reliability of high-performance hoses that deliver fracturing fluids safely under extreme pressure. This article explains how fracture networks form—the “underground highway” of unconventional resources—and why advanced hoses like Senflow super abrasion-resistant UPE hoses are vital for efficiency, safety, and production gains.

Durable Sandblasting Hoses: Ensuring Efficiency and Safety on Construction Sites

Large-scale construction projects demand not only robust materials but also reliable preparation processes. Sandblasting hoses play a critical role in cleaning steel surfaces, yet they face harsh conditions, including abrasion, extreme temperatures, and frequent bending. Senflow’s abrasion-resistant, weatherproof hoses provide consistent performance, extending service life, reducing downtime, and supporting safe, efficient project execution across diverse construction environments.

High-Performance Frac and Oil Hoses for Hydraulic Fracturing Operations

Hydraulic fracturing is essential for extracting hydrocarbons from low-permeability reservoirs. Safe, efficient fluid and proppant transport relies on high-pressure, super abrasion- and acid-resistant frac hoses and oil hoses. Senflow’s reinforced hoses ensure reliable performance under extreme pressure, abrasive conditions, and harsh chemicals, supporting stable and effective hydraulic fracturing works.